The production of the BMW M1

The production of the BMW M1

Parallel to all the turmoil surrounding the termination of the contract with Lamborghini and the construction of the seven E26/1 prototypes, solutions were feverishly sought for the production of at least 400 E26/1 vehicles.

The number of 400 identical basic vehicles, built in a maximum of 24 consecutive months, was a requirement in order to be able to compete at all in the aspired “Group 4” world championship.

The project E26/1 was about to fail, now the question was how to continue and who could take over the series production of the streetcars after the failure of Lamborghini. With the following companies involved, the M1 project was finally realized.

1. ItalDesign

ItalDesign was founded in 1968 by Giorgetto Giugiaro, Aldo Mantovani and Luigiano Bosi. Until the M1 order from BMW, the studio was commissioned to design and develop vehicles and build prototypes. The acquisition of the first stage of the BMW M1 meant that about 50 people were employed in production, but the space available for this purpose was far too small, so that desks had to be moved together in the office area.

The following work was carried out at ItalDesign:

- Painting of the lattice tube frame (supplied by Marchesi)

- Bodywork (supplied by T.I.R.) screwed and glued to the frame

- fine sanding, filler and painting

- glazing

- Installation of dashboard and complete electrical system

2. ItalEngineering

Former Lamborghini employees, including Pier Luigi Cappellini (Finance), Marco Raimondi (Chief Technical Officer), Sig. Dellorco (Procurement) and Fiorenzo Fiorini (Development) founded the company ItalEngineering and with their knowledge and experience continued to maintain the cooperation with ItalDesign, Lamborghini and the existing suppliers. Their task and specialty was the mediation of orders to the Italian companies known to them and the technical support of these partners before and during production.

3. Baur

BMW remembered the earlier cooperation with the coachbuilder Baur in Stuttgart and already at the end of July 1978 a corresponding contract could be signed between BMW and the Baur brothers. However, the working time initially calculated according to BMW’s specifications had to be increased by 50% due to the insufficient quality of the bodywork delivered by ItalDesign.

The following work was carried out at Baur:

- Removal of the Italian-assembled hoods, seats, center console, etc. so that access to the interior of the M1 was possible again.

- Relocation of brake and fuel lines

- Pre-installation of radiator and air conditioning

- Installation of the two fuel tanks and the oil tank on the side behind the seats

- Installation of shift linkage, steering gear, brake booster

- Pre-assembly of the wheel suspensions (wishbones delivered by Marchesi), with the ATE brake system and Bilstein shock absorbers

- Installation of wheel suspensions and axle halves

- Installation of steering column and pedals

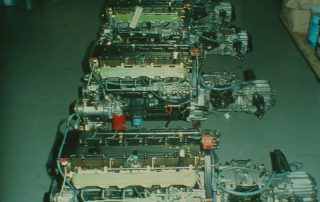

- Wedding = installation of the engine/transmission unit

- Filling of oil, brake fluid and water

- Bleeding of the brakes

- Finish with the reinstallation of the seats, center console and the two hoods

- Adjustment of the headlights

- Mounting of the steering wheel

4. BMW AG

After completion at Baur, the BMW M1s were put through their paces by quality inspectors from BMW AG in Stuttgart:

- optical measurement

- final inspection

- Test drive on the road

After the final inspection, the BMW M1s were delivered on car transporters to Munich, where they underwent a final check at BMW AG and were then handed over to their new owners in a special salesroom in Munich or at deffinated BMW M support points.

5. Subcontractors

These are listed separately below in the list of suppliers with their scope of delivery.

Definition of the assembly work with ItalDesign and Baur

| Scope | ItalDesign | Baur |

|---|---|---|

| Frame and body | in cooperation with subcontractors | – |

| Electrical system | Wiring harness, lights, instruments, horn, support plate for ignition | Engine wiring harness, ignition coil, switchgear, battery, radiator fans |

| Water system and air conditioning | Central pipes, heater and supply line, air conditioning evaporator, condenser, dryer | water cooler, front water pipes, hoses, air conditioning condenser, dryer bottle, connection work |

| Interior | dashboard, heating elements + operation, seats, switches, center console, speakers, floor mats | seat belts |

| Pedal block and actuators | Hood cables front + rear | Pedal block with pedals, throttle actuator and throttle cable |

| Windscreen wiper and washer system | Windscreen wiper with wiper bearings, motor and linkage, windscreen washer system | Windscreen washer reservoir with pump |

| Mirrors, brake system, clutch actuator | – | brake lines, clutch line, brake force regulator, vacuum line, brake hoses, booster, master cylinder, clutch master + slave cylinder, brake discs, brake calipers, hand brake complete, refill reservoir, connection work |

| Fuel and oil system | – | tanks, hoses, lines, filling ports, fuel pump with filter and bracket, fuel tank sensor, engine oil tank with all lines, engine connection work |

| Front axle suspension | – | pre- and final assembly, wishbones, wheel carriers, wheels, tires, stabilizers |

| Rear axle suspension | – | preliminary and final assembly, wishbones, wheel carriers, wheels, tires, stabilizers, drive shafts |

| Steering system | – | steering column, steering gear, steering wheel, steering damper, electrical connections steering column |

| Engine, clutch, gearbox | – | assembly of engine + gearbox, electrics, connection work, gearshift linkage complete, clutch operation |

| Exhaust system | – | pre- and final assembly exhaust manifold, intermediate pipe and muffler |

| Spare wheel and tools | – | pre-assembly and mounting |

| System fillings | – | water system, heating system, engine oil system, clutches, brake system |

| Final inspection | – | driving inspection, troubleshooting, adjustment work, vehicle measurement, finish and repainting, vehicle preservation, headlight adjustment |

Suppliers for the project E26/1

| Supplier | Country | Scope of delivery |

|---|---|---|

| ATE | Germany | brake calipers, brake force regulator, brake hoses, THZ |

| Bilstein | Germany | Shock absorbers |

| Bosch | Germany | Engine electrics |

| Brembo | Italy | handbrake caliper |

| Eberspächer | Germany | Exhaust system |

| Ehrenreich | Germany | Joints for wheel suspension and tie rods, hangers for stabilizers |

| Fichtel & Sachs | Germany | Clutch |

| Forcellini | Italy | water cooler |

| ItalDesign | Italy | Body and equipment |

| Jäger | Italy | Instruments |

| Löbro | Germany | Drive shafts |

| Magnet Marelli | Italy | Control unit, wiper motor |

| Marchesi | Italy | Chassis |

| Mecano-Bundy | Italy | Brake lines |

| Pirelli | Italy | tires |

| SHW | Germany | Brake discs |

| SWF | Germany | Electric motors |

| Speedline | Italy | alloy wheels Campagnolo |

| T.I.R. | Italy | GRP bodywork |

| TRW | Italy | Rack and pinion steering |

| ZF | Germany | Manual transmission with integrated axle drive |

Timing

At the beginning of March 1978 it was already foreseeable that the series of 400 units necessary for homologation could not be produced in the remaining time. Now Jochen Neerpasch and his team set up an emergency program that is still unparalleled today and will probably remain unique. The racing series “PROCAR” was started with the BMW M1 in the racing trim of the “Group 4” and held in 1979 and 1980, in each case in the run-up to the European Formula 1 Grand Prix. More about this in the separate chapter “PROCAR”.

So finally the series production of the BMW M1 customer cars with the chassis number 019 started with the following chronological sequence:

ItalDesign delivered on 30.11.1978 to Stuttgart to Baur

Baur delivered to BMW in Munich on 12.01.1979

BMW delivered on 02.02.1979 to BMW M base in Dinslaken

Production numbers and chassis numbers (WBS 59910004301 – 001 to 460)

BMW officially assigned 460 chassis numbers. Of these, however, 5 were test chassis and two vehicles that were not built. According to the BMW production list, 453 BMW M1 cars were built, of which 399 were BMW M1 Streetcars and 54 BMW M1 Procars.

In addition there are 3 known replicas with unofficial chassis numbers starting from 461 ascending, which were built by the company AHG Gartemann in Bielefeld.

Color and upholstery of the BMW M1 Streetcar

To the spiral bound BMW M1 brochure there was a separate overview of the five offered exterior colors in white, orange, red, blue and gray and the two interior colors in black and brown, the production of the 399 pieces BMW M1 Streetcars was delivered as follows:

Factory colors

| White | 163 vehicles |

| Orange | 98 vehicles |

| Red | 71 vehicles |

| Blue | 59 vehicles |

| Gray | 4 vehicles |

Special paint

| Silver | 2 vehicles |

| Black | 2 vehicles |

Interior design

| Black | 390 vehicles |

| Brown | 9 vehicles |

Literature

- Motorbuch Verlag: Cars that made history, BMW M1 by Lothar Boschen

- Delius Klasing: BMW M1, The Story by Jochen Neerpasch / Jürgen Lewandowski

- Motorbuch Verlag: LAMBORGHINI, All models until today by Serge Bellu

Erich Matter – Februar 2016